In modern manufacturing, aluminum alloys are widely used in aerospace, automobile manufacturing, electronic equipment and other fields because of their light weight, high strength and good corrosion resistance. However, the aluminum chips produced during the processing of aluminum alloys are often regarded as industrial waste. If not handled properly, it will not only cause a waste of resources, but may also have a negative impact on the environment. The emergence of Aluminum shavings Briquetting Machine provides an efficient and environmentally friendly solution to this problem.

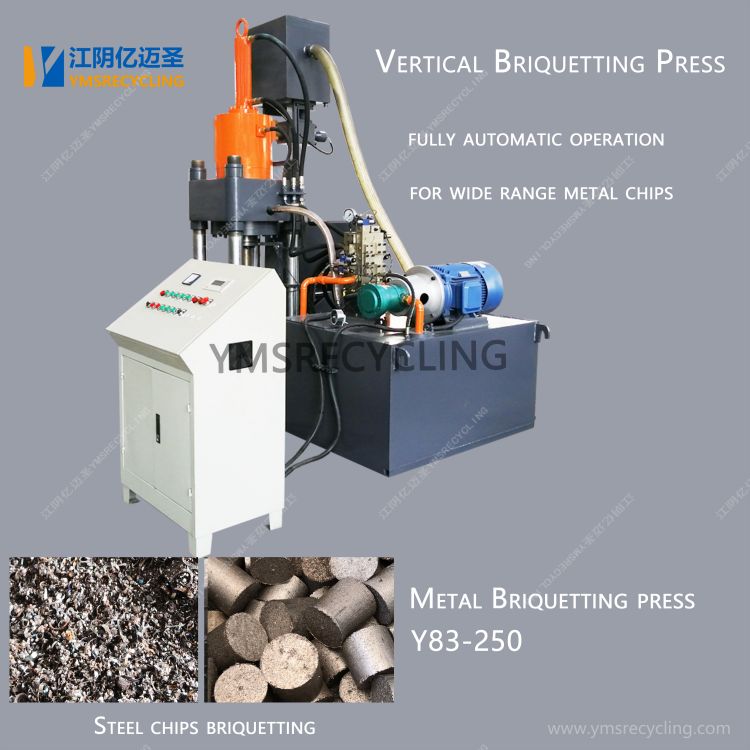

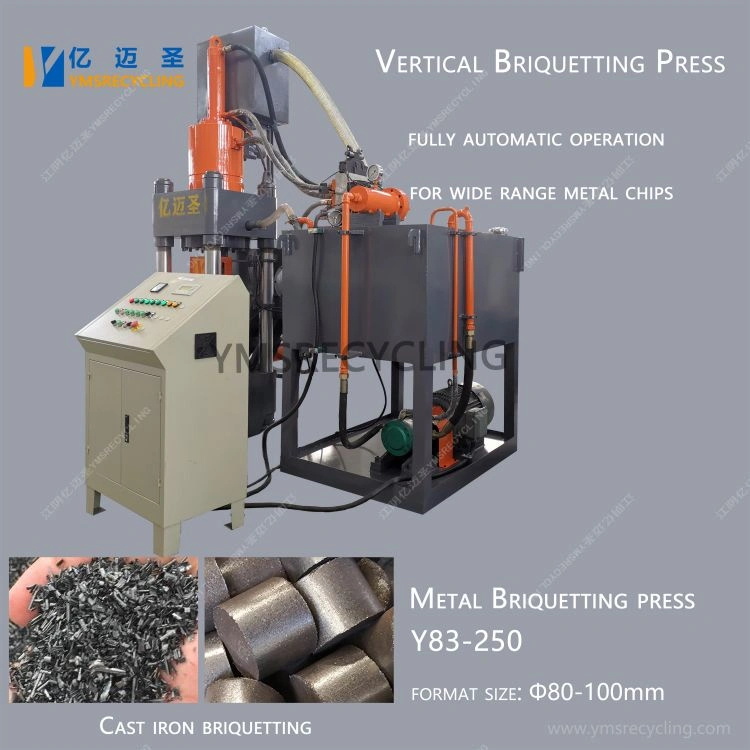

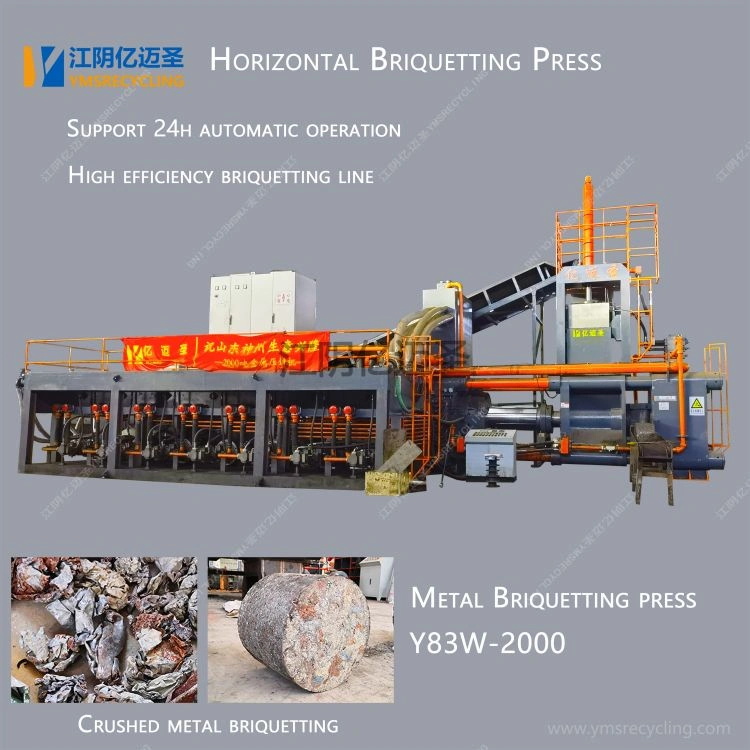

Aluminum shavings Briquetting Machine is a device that uses mechanical force to compress loose, irregular aluminum shavings into high-density, regular-shaped blocks. Its core working principle is to use strong hydraulic or mechanical pressure to compact aluminum chips tightly in the mold, thus greatly reducing the volume and facilitating storage and transportation. This process not only increases the density of aluminum chips, but also facilitates subsequent smelting and reuse, achieving efficient recycling of resources.

Significant advantages of aluminum chip briquetting machine

Efficient resource recovery: Through briquetting, the volume of aluminum chips is greatly reduced and the density is significantly increased, allowing the energy consumption and raw material loss during the smelting process to be effectively controlled. This not only reduces production costs but also improves resource utilization.

Environmental protection and energy saving: The aluminum chip briquetting machine does not need to add any adhesive during the production process, avoiding the introduction of chemical substances and reducing environmental pollution. At the same time, efficient briquetting treatment reduces waste emissions and is in line with the concept of green manufacturing.

Improved smelting efficiency: The aluminum chips after briquetting have regular shapes and are easy to feed and smelt, improving the production efficiency of the furnace and the purity of the aluminum material. Briqueted aluminum chips are smelted faster and consume less energy, further reducing production costs.

Easy to store and transport: After the aluminum chips are briquetted, the volume is greatly reduced, making it easy to stack and store, reducing the need for storage space. At the same time, regular blocks facilitate mechanized handling and long-distance transportation, reducing logistics costs.

With the increasing global awareness of environmental protection and resource recycling, Aluminum shavings Briquetting Machine has broad application prospects in the manufacturing industry. Especially in industries that use large amounts of aluminum alloys, such as automobile manufacturing, aerospace, and electronic equipment, aluminum chip briquetting machines have become indispensable environmental protection equipment.

In the field of automobile manufacturing, as the trend of lightweighting intensifies, aluminum alloy castings are increasingly used. However, the amount of aluminum chips generated during the processing of aluminum alloys is huge. If not processed in time, it will seriously affect production efficiency and cost control. The introduction of the aluminum chip briquetting machine effectively solves this problem and provides automobile manufacturers with an efficient and environmentally friendly aluminum chip processing solution.

In the aerospace industry, aluminum alloys are widely used due to their lightweight and high-strength properties. However, aerospace devices have extremely high requirements on materials, and any tiny impurities may affect the performance of the device. The aluminum chip briquetting machine ensures the quality of aluminum alloy materials through efficient compaction and pure smelting, providing strong support for the development of the aerospace industry.