On the vast stage of metal recycling and reuse, heavy scrap metal shear machines have become the shining stars of this green revolution with their unparalleled power and extreme precision. These behemoths not only carry the weight of the progress of industrial civilization, but are also an important force in promoting resource recycling and sustainable development.

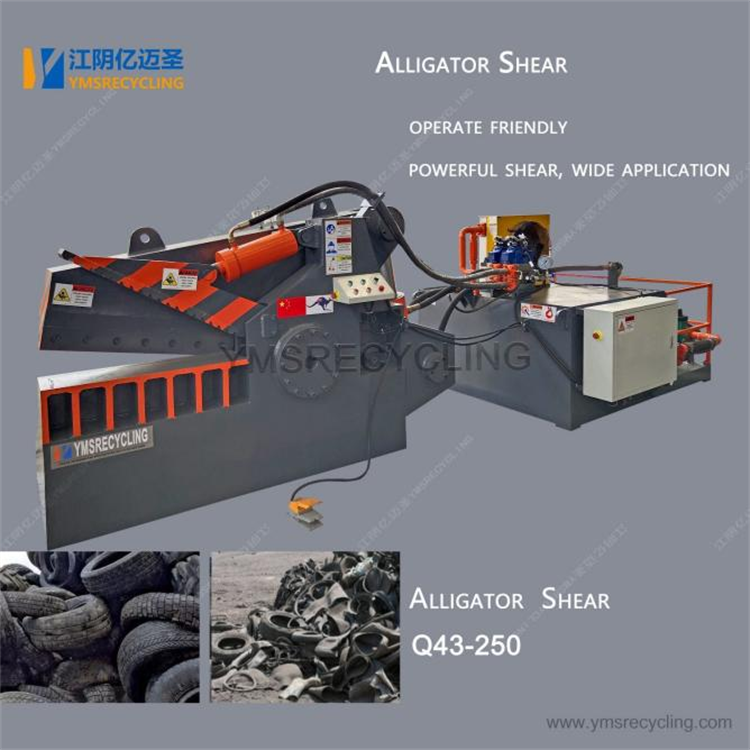

The primary feature of heavy scrap metal shear machines is their stunning power. These machines convert power into tons of shearing force through precisely designed hydraulic or mechanical transmission systems, easily dealing with scrap metal of various shapes, sizes, and materials. Whether it is a heavy car body, a huge mechanical part, or a complex steel structure, it all looks so fragile under the giant blade of a heavy-duty scrap metal shear. This display of power is not only a symbol of technological progress, but also a combination of human wisdom and industrial power.

However, heavy scrap metal shear machines are not just a pile of power, their pursuit of precision is equally admirable. Supported by strong power, these machines are equipped with high-precision control systems and blade designs, which can achieve precise shearing of scrap metal. Whether it is cutting angle, size or shape, it can meet extremely high precision requirements. The realization of this precision is due to the rapid development of modern manufacturing technology, as well as the in-depth understanding and application of material science and mechanical principles. It is this persistent pursuit of precision that makes heavy scrap metal shear machines play an irreplaceable role in the field of metal recycling.

The reason why heavy scrap metal shear machines can achieve the fusion of power and precision is inseparable from the strong support of technological innovation. Manufacturers continue to invest in research and development resources, adopt new materials, new processes, and new technologies to comprehensively upgrade and optimize equipment.

High-strength alloy steel is used as the blade material, and after special heat treatment process, the blade is more wear-resistant and corrosion-resistant; the introduction of intelligent control system realizes the automatic operation and remote monitoring of equipment; the optimization of transmission system and mechanical structure design improves the stability and reliability of equipment. These technological innovations not only improve the performance and efficiency of the equipment, but also make the fusion of power and precision reach an unprecedented level.

As a leader in the field of metal recycling, heavy scrap metal shear machines have won wide praise and recognition for their powerful power and extreme precision. In the future development, these machines will continue to play an important role in promoting resource recycling and promoting sustainable development.