Hydraulic scrap metal baler machine is a device that uses hydraulic principles to compress and pack scrap metal. It compresses metal scraps tightly under strong hydraulic pressure to form regular bales, thereby greatly saving storage space and facilitating subsequent transportation and reuse. This kind of machine not only improves the efficiency of waste processing, but also significantly reduces processing costs, injecting new vitality into the sustainable development of enterprises.

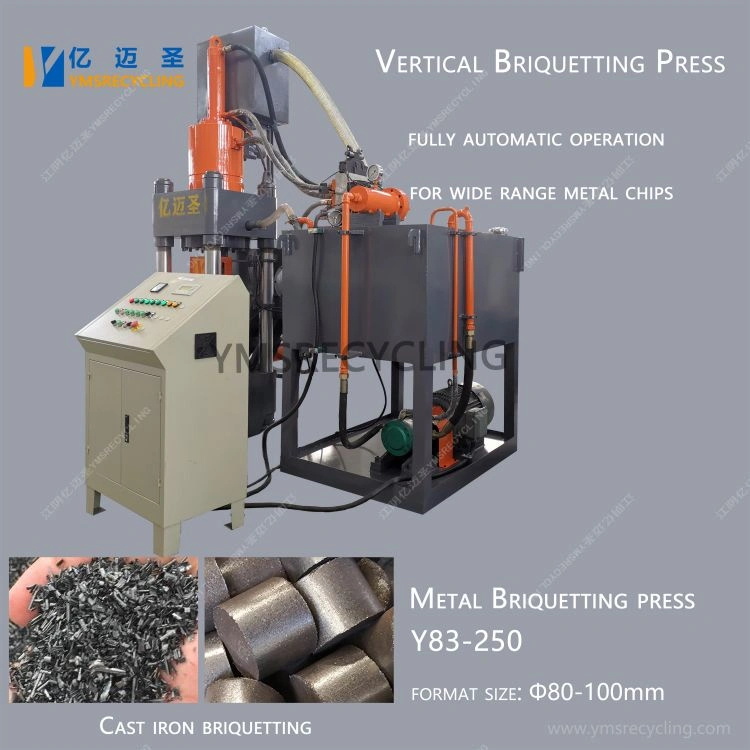

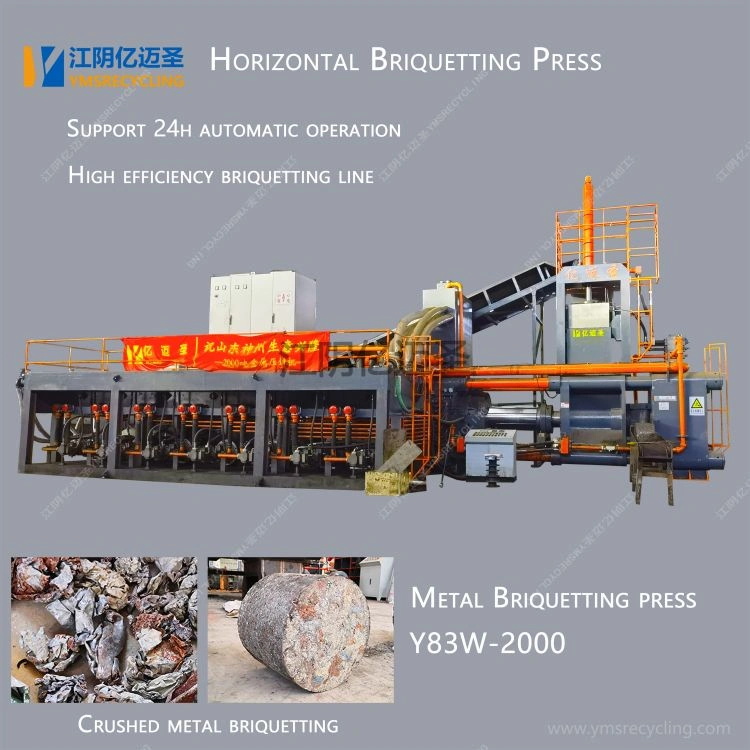

From a structural point of view, a hydraulic metal baler usually consists of a power system, a hydraulic system, a control system, a compression chamber and a discharging mechanism. The power system provides power support for the entire equipment, and the hydraulic system is the core component that realizes the compression function. Through the transmission of high-pressure oil, it drives the compression piston to compress the metal scrap. The control system is responsible for monitoring the operating status of the equipment to ensure that various parameters are in the best condition, while providing a humanized operation interface to facilitate users to make various settings and adjustments.

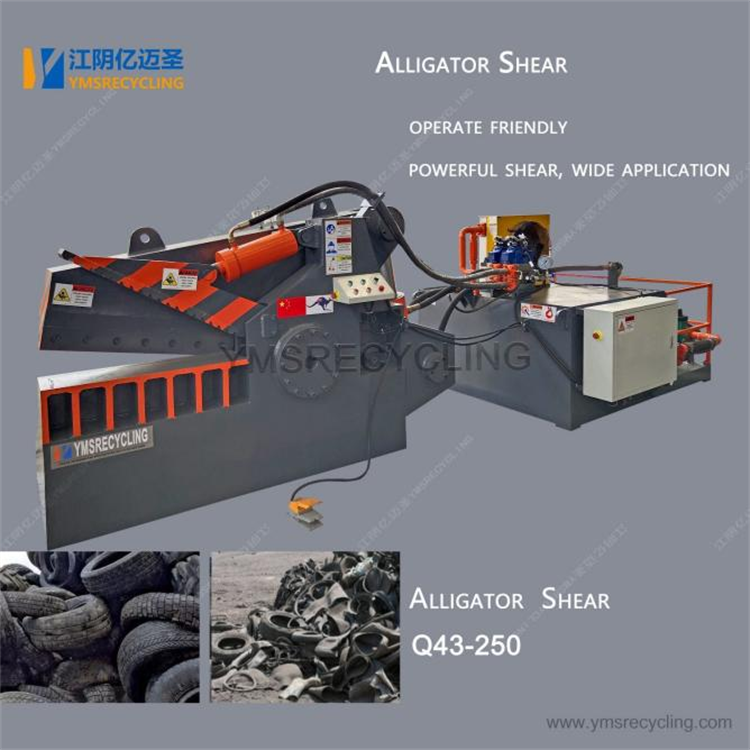

In practical applications, hydraulic scrap metal baler machine have demonstrated their incomparable advantages. First of all, it has a high compression ratio and can compress originally loose and bulky metal scraps into tight bales, which greatly saves storage space. Secondly, due to the hydraulic transmission method, the equipment has low noise and vibration during operation, and has less interference with the surrounding environment. The hydraulic metal baler also has the characteristics of easy operation and maintenance. Users can operate it after simple training, which greatly reduces labor costs.

In terms of environmental protection, hydraulic scrap metal baler machine also perform well. By compressing and baling, scrap metal can be stored and transported more compactly, reducing energy consumption and emissions during transportation. Packaged metal scraps are easier to recycle, thereby reducing resource waste and environmental pollution. This green and environmentally friendly treatment method not only conforms to the current social development trend, but also wins a good social reputation for the company.

With the continuous advancement and innovation of technology, hydraulic scrap metal baler machine are also constantly upgraded and improved. For example, some advanced equipment has implemented automated control and can automatically adjust compression parameters according to the type and quantity of metal scrap to ensure the best compression effect. In addition, some equipment is equipped with intelligent monitoring systems, which can monitor the operating status and fault conditions of the equipment in real time, providing great convenience for equipment maintenance and management.

Going forward, hydraulic scrap metal baler machine will play an even more important role in scrap management. As the world attaches increasing importance to environmental protection and resource reuse, hydraulic scrap metal baler machine will become the equipment of choice for more companies due to their high efficiency and environmental protection. At the same time, with the continuous advancement and innovation of technology, we also look forward to seeing the advent of more hydraulic scrap metal baler machine with more complete functions and better performance, contributing more to the sustainable development of mankind.