In today's rapidly developing industrial field, efficient and environmentally friendly resource processing and recycling have become one of the key factors for the sustainable development of enterprises. Against this background, Custom metal baler machine (Custom Metal Baler Machine) is gradually becoming an indispensable equipment in many industries with its performance, high flexibility and adaptability.

Traditional metal packaging equipment often faces the problems of single function and poor adaptability, and it is difficult to meet the processing needs of metal waste of different materials, shapes and sizes. The Custom metal baler machine achieves a highly customized response to customer needs through modular design and advanced manufacturing technology. Whether it is thin and fragile aluminum sheets, heavy steel scraps, or irregularly shaped scrap auto parts, the custom machine can ensure the best packaging effect and material compression ratio by adjusting the pressure system, feed port size and packaging cavity structure, maximize the use of storage space and reduce logistics costs.

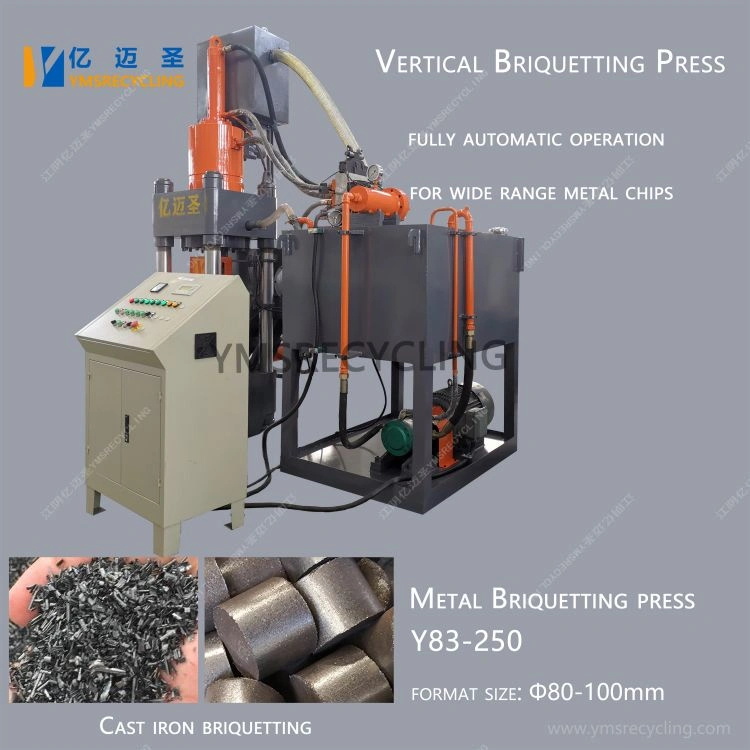

With the continuous advancement of the Internet of Things and artificial intelligence technology, Custom metal baler machine is gradually moving towards intelligence and automation. By integrating sensors, remote monitoring systems and intelligent algorithms, the equipment can monitor the operating status in real time, predict maintenance needs, and even automatically adjust parameters before a failure occurs to avoid downtime. In addition, the automated control system makes operation easier, reduces manual intervention, and improves operational safety and production efficiency. Some high-end custom models are also equipped with automatic identification systems that can distinguish different types of metal materials, further optimize the packaging process, and reduce the error rate.

Today, as environmental protection is increasingly valued, Custom metal baler machine has become an important force in promoting industrial green transformation with its outstanding energy-saving and consumption-reducing capabilities. By adopting advanced hydraulic system design and energy recovery technology, the machine can effectively reduce energy consumption and carbon emissions during operation. At the same time, efficient metal compression packaging not only reduces the volume of waste, facilitates long-distance transportation and storage, but also facilitates subsequent metal recycling and reuse, promotes the circulation of resources, reduces dependence on new raw materials, and conforms to the concept of sustainable development.

From the processing of scrap parts in automobile manufacturers, to the recycling of metals in scrap electronic products, to the management of steel scraps in the construction industry, Custom metal baler machine has demonstrated its strong vitality in applications in all walks of life. For example, after an automobile manufacturer introduced a customized baling machine, it successfully transformed the originally scattered metal waste into compact bales, which not only greatly improved the utilization rate of storage space, but also achieved rapid monetization of waste through close cooperation with recycling companies, thereby increasing the company's economic benefits.