In the modern industrial field, metal recycling and processing has become an indispensable part. With the continuous advancement of technology, Custom Metal Baler Machine is leading the new trend in the metal recycling industry with its high efficiency, flexibility and strong adaptability.

The biggest advantage of Custom Metal Baler is its high flexibility and adaptability. Traditional metal balers can only handle metal scraps of a certain type or size, while customized equipment can be designed and manufactured according to the actual needs of customers. This means that whether it is processing light and thin aluminum sheets, heavy steel plates, or complex metal scraps, Custom Metal Baler can provide the best solution.

Custom Metal Baler also excels in energy saving, environmental protection and safety. By adopting advanced hydraulic systems and intelligent control systems, these devices can minimize energy consumption and noise pollution while ensuring efficient operation. At the same time, its sturdy and durable structure and multiple safety protection measures ensure the safety of operators.

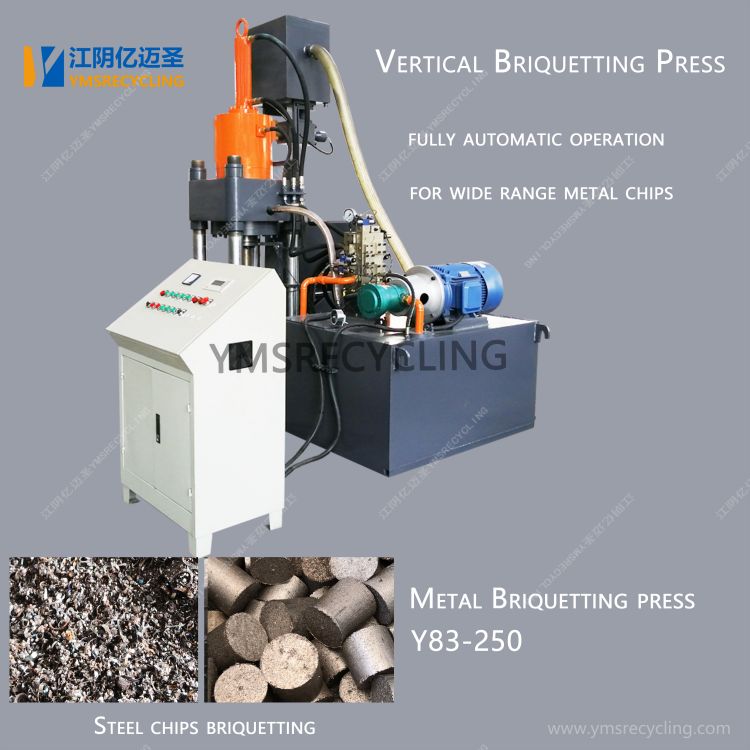

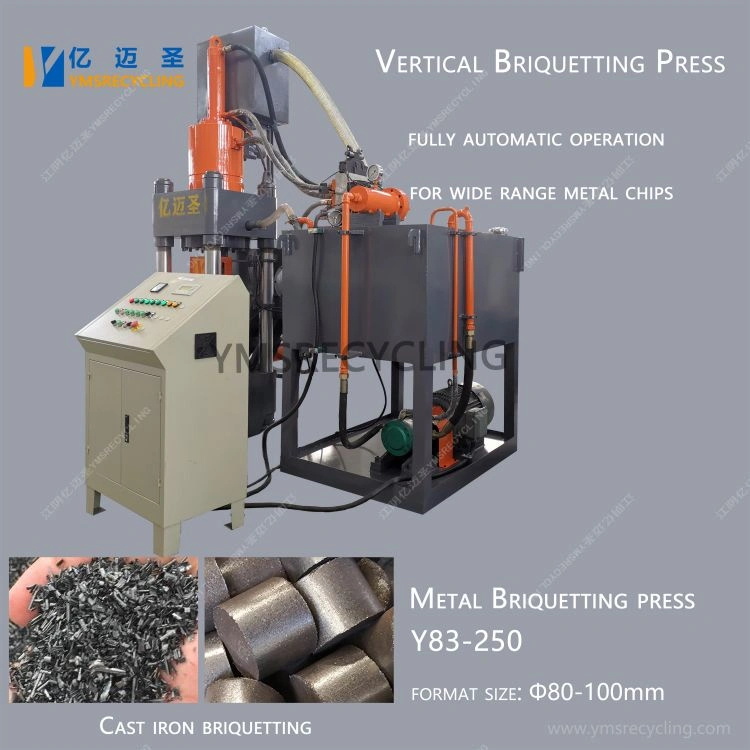

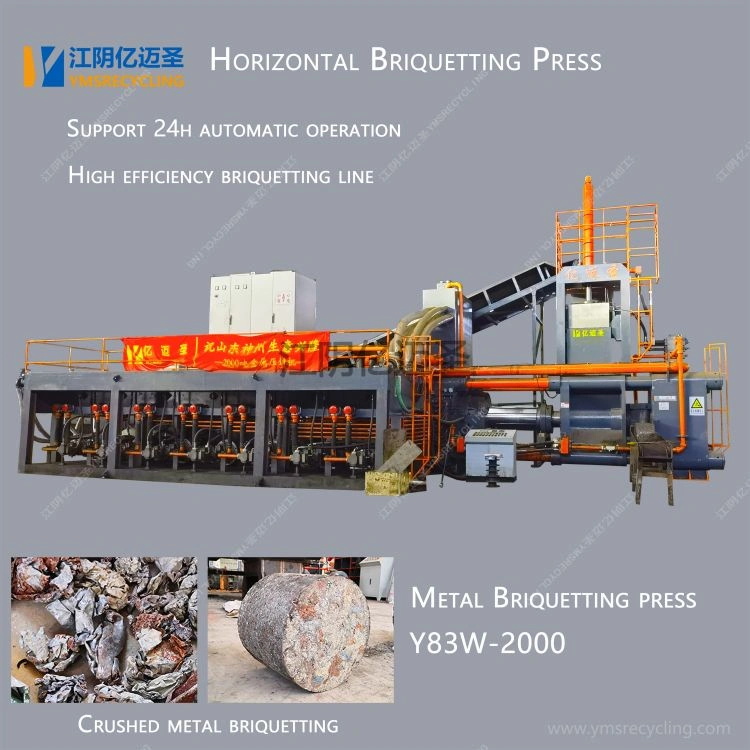

The working principle of Custom Metal Baler is mainly based on hydraulic transmission and mechanical compression technology. The equipment usually consists of a feed port, a compression chamber, a hydraulic system, an electrical control system, and a discharge port. During operation, metal waste enters the compression chamber through the feed port, and the hydraulic system drives the pressure head to compress the waste until a compact block is formed. The block is then discharged through the discharge port for subsequent transportation and processing.

Customized metal balers have broad application prospects in the metal recycling industry. In large enterprises such as steel mills, aluminum processing plants, and automobile manufacturers, these devices are used to process metal waste generated during the production process, achieving effective recycling and reuse of resources. At the same time, in places such as scrap recycling stations and garbage disposal centers, customized metal balers also play an important role, helping to reduce the volume of garbage and improve transportation efficiency.

With the continuous improvement of environmental awareness, the application of customized metal balers in the field of environmental protection is also becoming more and more extensive. For example, in the fields of electronic waste treatment and scrap car dismantling, these devices can efficiently process waste containing metal components, reduce environmental pollution, and promote the recycling of resources.

With the advancement of technology and the continuous changes in the market, customized metal balers are developing in a more intelligent, efficient and environmentally friendly direction. In the future, these devices will pay more attention to the integration with technologies such as the Internet of Things and big data to achieve functions such as remote monitoring, fault warning and intelligent scheduling.

Customized metal balers are becoming an indispensable and important tool in the metal recycling industry with their unique advantages, efficient working principles and wide application fields. In the future, with the continuous advancement of technology and the continuous expansion of the market, customized metal balers will continue to lead the new trend of the metal recycling industry and make greater contributions to the recycling and sustainable development of resources.