In today's era of increasingly scarce resources, the recycling of scrap metal has become a key link in promoting a circular economy and achieving sustainable development. With the rapid advancement of science and technology, Scrap Metal Recycle Machines are leading a green revolution in resource regeneration with unprecedented innovation.

The traditional scrap metal recycling process often relies on a lot of manual labor, which is not only inefficient but also has safety hazards. Modern scrap metal recycling machines integrate advanced sensor technology, artificial intelligence algorithms and machine vision systems to achieve fully automated operations from sorting, crushing to classification. These machines can accurately identify different types of metal materials, such as iron, aluminum, copper, etc., effectively avoiding the waste of resources caused by mixed processing. Through big data analysis, the machine can also optimize the workflow, predict maintenance needs, and ensure continuous and efficient operation.

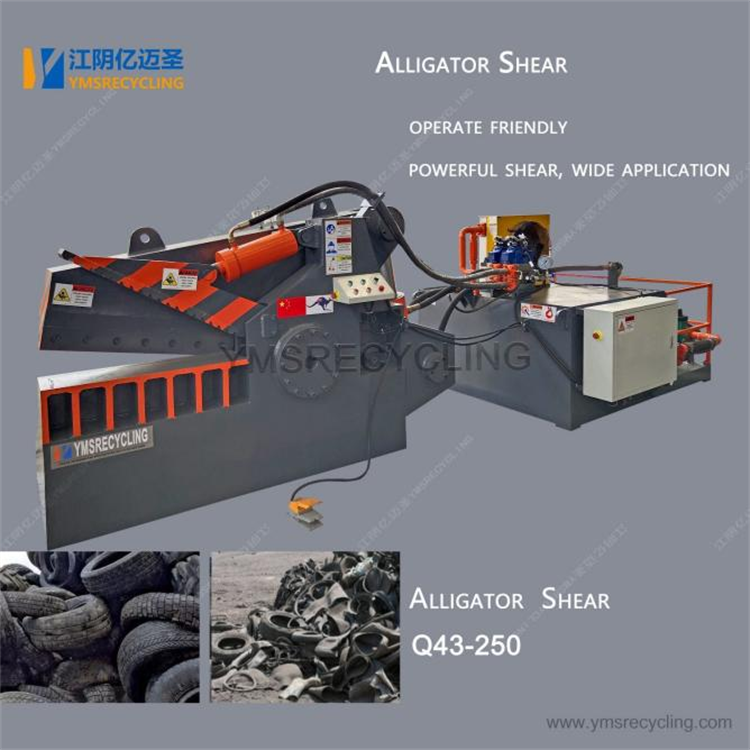

The crushing of scrap metal is an important part of the recycling process, but traditional methods are often accompanied by high energy consumption and noise pollution. The new generation of scrap metal recycling machines adopts more environmentally friendly crushing technologies, such as low-temperature crushing and hydraulic crushing, which not only greatly reduce energy consumption, but also significantly reduce noise and dust emissions. In particular, low-temperature crushing technology effectively avoids metal oxidation by controlling the temperature during the crushing process, improves the purity of recycled materials, and creates more favorable conditions for subsequent reuse.

Scrap metals are often mixed with non-metallic impurities. How to achieve efficient separation is the key to improving the quality of recycling. Modern recycling machines combine efficient magnetic separation technology and eddy current separation technology. The former uses the responsiveness of metals to magnetic fields for separation, which is particularly suitable for the extraction of ferrous metals; the latter is based on the eddy current effect generated by metal particles in an alternating magnetic field to achieve effective separation of non-magnetic metals (such as aluminum and copper). The combination of these two technologies has made the purity of scrap metal recycling reach an unprecedented level, providing high-quality raw materials for subsequent smelting and processing.

Under the guidance of the concept of circular economy, the design of scrap metal recycling machines pays more and more attention to modularity, disassembly, and the recyclability of materials. This not only facilitates the maintenance and upgrading of the machine and extends its service life, but also reduces the generation of waste and realizes the full life cycle management from design to scrapping. In addition, some cutting-edge companies are exploring the combination of recycling machines with renewable energy (such as solar energy and wind energy) to further reduce carbon footprint and promote the green transformation of the entire recycling industry.

As an important part of the circular economy system, the technological innovation of scrap metal recycling machines is not only related to the efficient use of resources, but also a key step for humans to cope with environmental challenges and move towards a sustainable future. With the continuous breakthroughs in intelligent and green technologies, we have reason to believe that the future of scrap metal recycling will be more efficient and environmentally friendly, and contribute indispensable forces to the sustainable use of earth resources. In this green revolution, scrap metal recycling machines are leading us to a brighter and more sustainable future with their unique charm.