In the field of modern industry and environmental protection, hydraulic metal baler (Hydraulic Scrap Metal Baler Machine) as an efficient and energy-saving equipment is playing an increasingly important role. This machine can not only compress scrap metals such as steel, copper, aluminum, etc. into compact blocks for easy storage and transportation, but also effectively reduce transportation costs and improve smelting efficiency.

The working principle of hydraulic metal baler is based on advanced hydraulic transmission technology. The hydraulic oil is injected into the cylinder through a high-pressure oil pump to drive the piston to move, thereby generating a strong compression force. This force is enough to compress the scrap metal into tight and regular blocks. The machine has an exquisite structural design, including key components such as pump body, diffusion nozzle, steam duct, oil pan, heater, diffuser, cooling system and injection nozzle. Among them, the fractionation and purification process of pump oil is crucial to improve the ultimate vacuum and exhaust performance of the machine.

In terms of structure, hydraulic metal balers usually adopt modular design, which is easy to maintain and upgrade. For example, the HC81 series hydraulic metal balers can customize the size of the press box, the size and shape of the bale according to customer needs, and support manual valve control or PLC control, which can flexibly adapt to different working environments and needs.

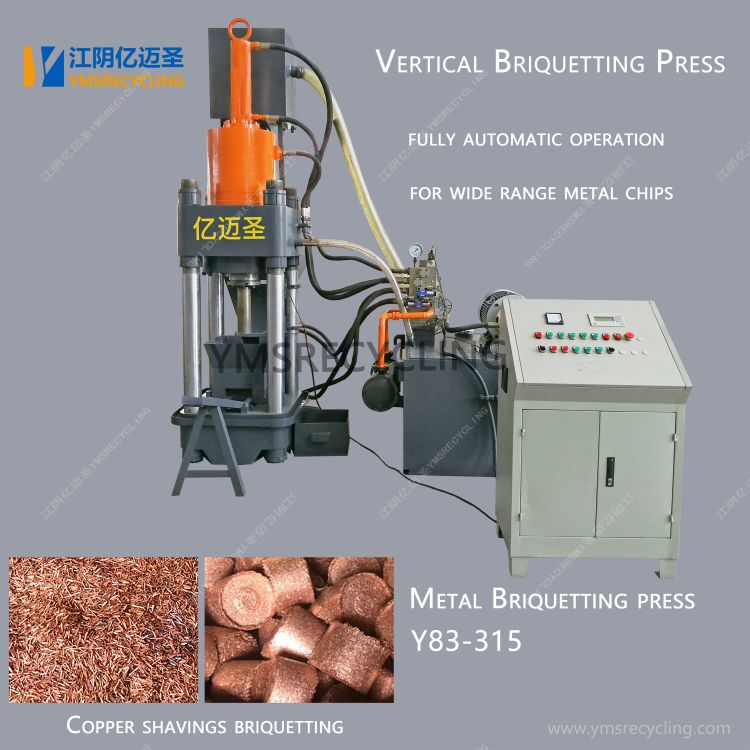

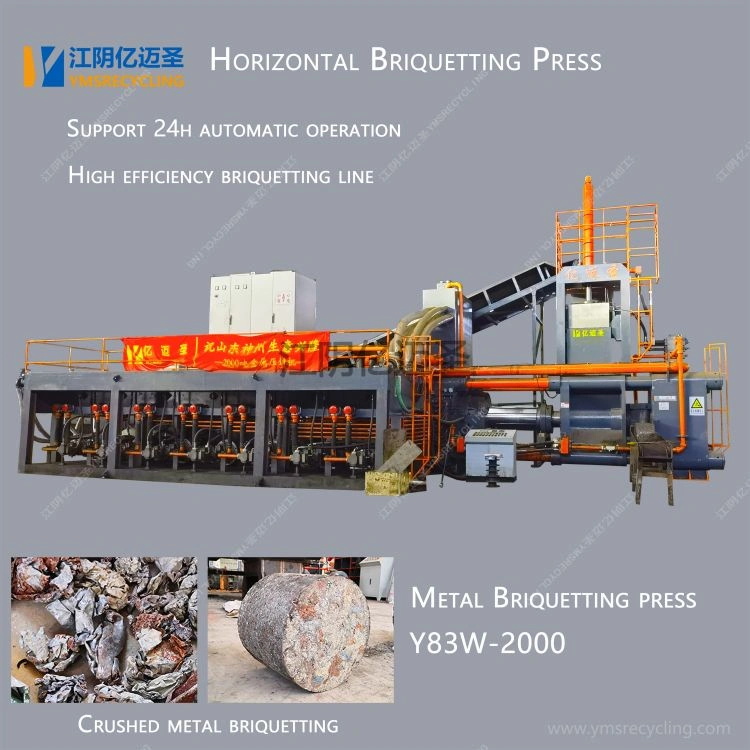

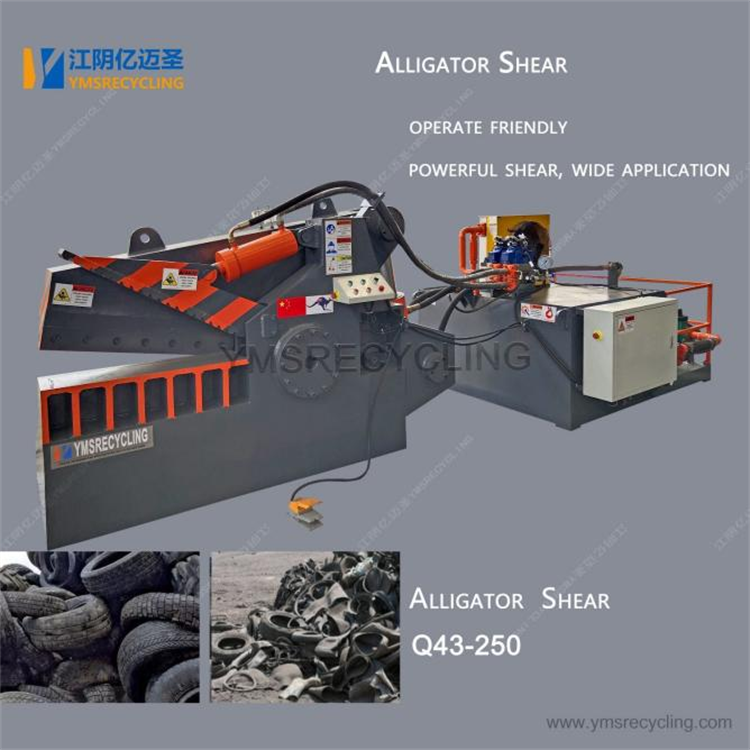

The application field of hydraulic metal balers is wide, covering many fields such as steel mills, recycling companies, and non-ferrous metal smelting industries. In steel mills, it can compress metal waste such as scrap steel and scrap iron into bales that are easy to smelt, thereby improving smelting efficiency; in recycling companies, it can pack scrap metal into regular bales, which is convenient for storage and transportation and reduces logistics costs. Hydraulic metal balers are also widely used in the non-ferrous metal smelting industry, such as the recycling and reuse of metals such as copper and aluminum.

From an environmental protection perspective, hydraulic metal balers are of great significance in promoting resource recycling and reducing environmental pollution. By compressing scrap metal, it can not only reduce the volume of waste, reduce storage and transportation costs, but also improve smelting efficiency, reduce energy consumption and carbon emissions. In addition, the hydraulic metal baler also adopts advanced oil circulation and purification technology to ensure that the machine does not produce harmful substances during operation, further protecting the environment.

With the advancement of science and technology and the development of industry, hydraulic metal balers are also constantly innovating and improving. On the one hand, manufacturers improve the durability and reliability of machines by adopting more advanced materials and processes; on the other hand, they are constantly exploring new application areas and market demands to promote the widespread application and sustainable development of hydraulic metal balers.

In the future, hydraulic metal balers will develop in a more intelligent and automated direction. For example, by introducing Internet of Things technology, remote monitoring and fault diagnosis can be achieved; by adopting advanced sensors and control systems, more precise compression and block shape control can be achieved. With the continuous improvement of environmental awareness and the promotion of policies, hydraulic metal balers will play a more important role in resource recycling and environmental protection.