In the realm of manufacturing and recycling, the metal baler machine has emerged as a cornerstone equipment, especially for industries dealing with large volumes of scrap metal. A custom metal baler machine, tailored to specific needs, can significantly enhance operational efficiency and waste management practices.

What is a Custom Metal Baler Machine?

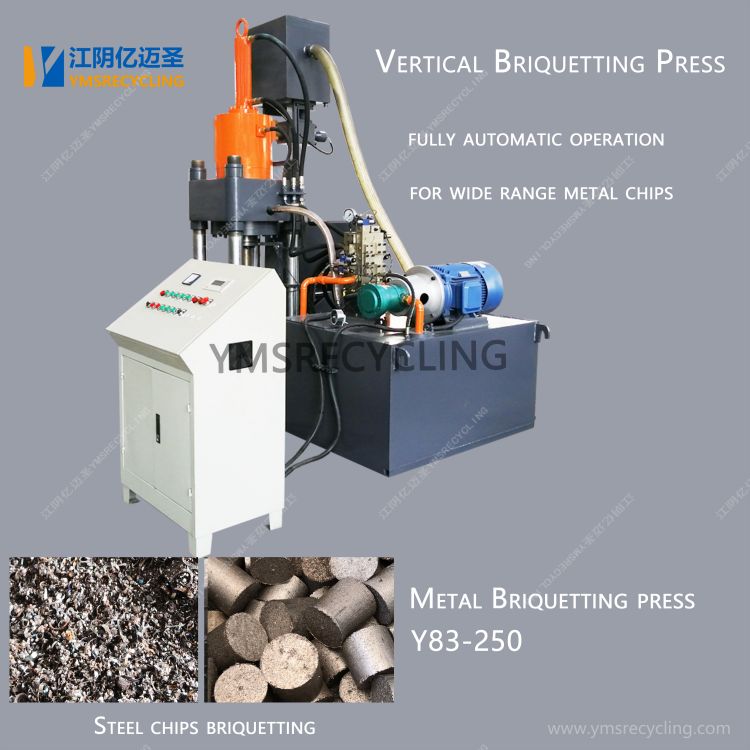

A custom metal baler machine is a specialized piece of equipment designed to compress and compact metal scraps into dense, manageable blocks or bales. These machines are often custom-built to meet the unique requirements of various industries, ensuring optimal performance and reliability. Whether it's the size of the bales, the type of metal processed, or the specific pressure needed, a custom metal baler machine can be tailored to suit almost any scenario.

The working principle of a metal baler machine, whether custom or standard, is based on hydraulic pressure. The machine comprises several key components: a feeding system, a hydraulic system, a compression chamber, and an ejection system.

Feeding System: The metal scraps are fed into the compression chamber through a conveyor belt or a spiral feeder. This ensures a steady and consistent supply of material.

Hydraulic System: The hydraulic system provides the necessary force to compress the metal scraps. It consists of a hydraulic pump, cylinders, and valves. When activated, the pump pushes hydraulic oil into the cylinders, causing the pistons to move and apply pressure to the metal scraps.

Compression Chamber: The metal scraps are compressed within the chamber under immense pressure, forming dense bales. The chamber walls are reinforced to withstand the high pressures involved.

Ejection System: Once the desired bale density is achieved, the ejection system pushes the bale out of the chamber, ready for transportation or further processing.

Benefits of Custom Metal Baler Machines

Efficiency: Custom metal baler machines are designed to maximize operational efficiency. They can handle larger volumes of metal scraps in shorter periods, reducing labor costs and downtime.

Flexibility: Customization allows for flexibility in terms of bale size, metal type, and pressure requirements. This ensures that the machine is perfectly suited to the specific needs of the industry.

Durability: Custom-built machines are often made with higher-quality materials and components, ensuring longer lifespans and reduced maintenance costs.

Environmentally Friendly: By compacting metal scraps into dense bales, custom metal baler machines reduce transportation costs and environmental impact. This makes them an ideal choice for industries committed to sustainability.

Custom metal baler machines have a wide range of applications across various industries。

Manufacturing Plants: Factories often generate large amounts of metal scraps during production. Custom metal baler machines help in compacting these scraps, reducing waste and facilitating recycling.

Construction Works: In the construction industry, metal scraps such as reinforcing steel bars and metal framing can be compacted into bales for easier disposal or recycling.

Energy & Mining: Mining operations generate significant amounts of metal waste. Custom metal baler machines help in managing this waste efficiently, ensuring compliance with environmental regulations.

Building Material Shops: Scrap metal from demolition projects can be compressed into bales, making them easier to transport and recycle.