In modern industrial manufacturing, metal cutting, turning, milling and other processes will generate a large amount of metal scraps, such as iron scraps, copper scraps, aluminum scraps, etc. These scraps not only take up a lot of storage space, but also easily scatter during transportation, increasing logistics costs. Metal scraps corrode quickly, resulting in reduced material value. In order to solve these problems, the Scrap Metal Chips Briquetting Machine came into being, and with its high efficiency and environmental protection, it plays an important role in the metal recycling industry.

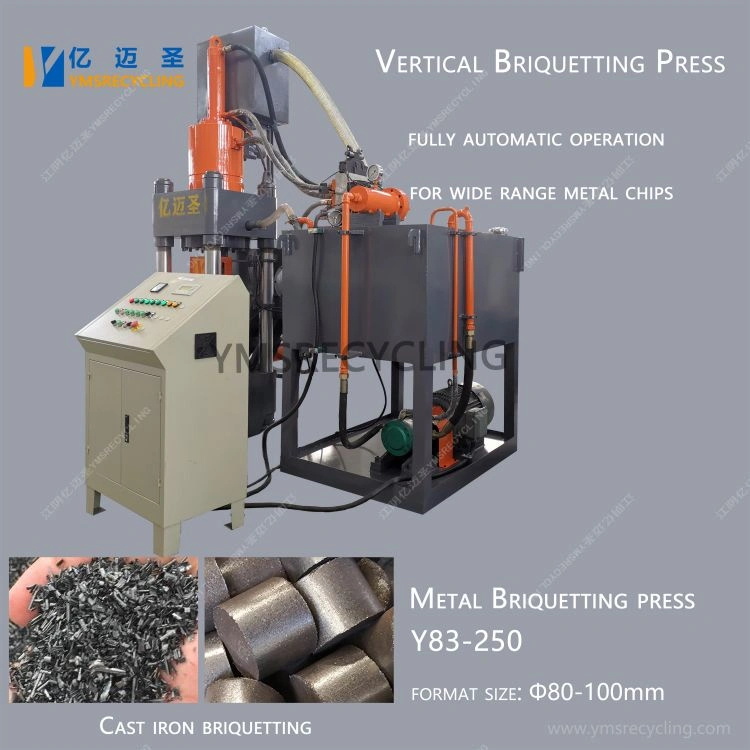

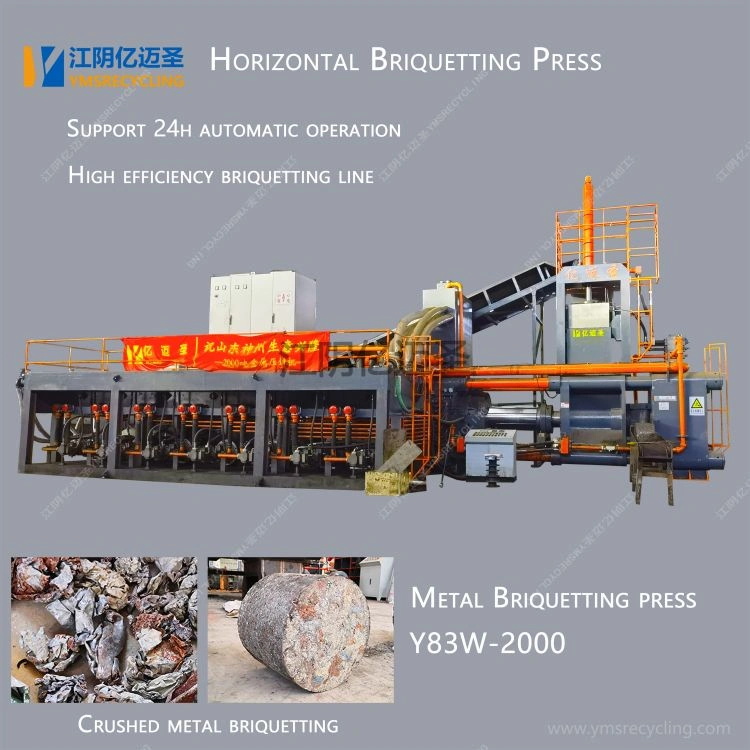

The Scrap Metal Chips Briquetting Machine, also known as the Scrap Metal Chips Forming Machine or the High-density Scrap Metal Chips Briquetting Machine, mainly uses hydraulic pressure to press the plastically deformable metal scraps into high-density solid blocks. In this process, there is no need to add temperature or other additives, and cold pressing is directly carried out to ensure the stability of the raw material properties. The briquetting metal blocks have consistent shape, size and weight, which is convenient for stacking and transportation, greatly reducing logistics costs.

The main advantages of metal scrap briquetting machines are reflected in the following aspects:

Save logistics costs: The metal after briquetting has high density and reduced volume, which is convenient for storage and transportation, significantly reducing logistics costs.

Improve smelting efficiency: Compared with loose metal scraps, the metal blocks after briquetting burn more fully during the smelting process, can produce more metal, and improve smelting efficiency.

Increase sales revenue: Due to their high density and consistency, the metal blocks after briquetting are easier to sell on the market, thereby increasing sales revenue.

Environmental protection and energy saving: The metal scrap briquetting machine does not need to add any additives during the production process, and the cold pressing process does not produce pollution, which meets environmental protection requirements.

Metal scrap briquetting machines are widely used in various metal recycling industries, including the briquetting of metal scraps such as iron scraps, copper scraps, aluminum scraps, alloy powders, stainless steel scraps, iron ore powders, magnesium powders, copper powders, etc. In addition, the machine can also be used for the briquetting of non-metallic materials such as coke and slag powder.

In order to meet the needs of different customers, many manufacturers provide customized services. For example, the shape of the briquette can be customized according to the specific requirements of customers, such as cylindrical, square, triangular, etc. This flexibility enables the metal chip briquetting machine to be more widely used in various industrial scenarios.