In the vast starry sky of modern industry, the hydraulic metal shearing machine is undoubtedly the dazzling star, illuminating every corner of the metal processing field with its unparalleled cutting power and precision. This is not just a machine, it is the crystallization of technological innovation and process progress, the fusion of engineer wisdom and craftsmanship, and is leading the metal processing industry towards a more efficient and intelligent future.

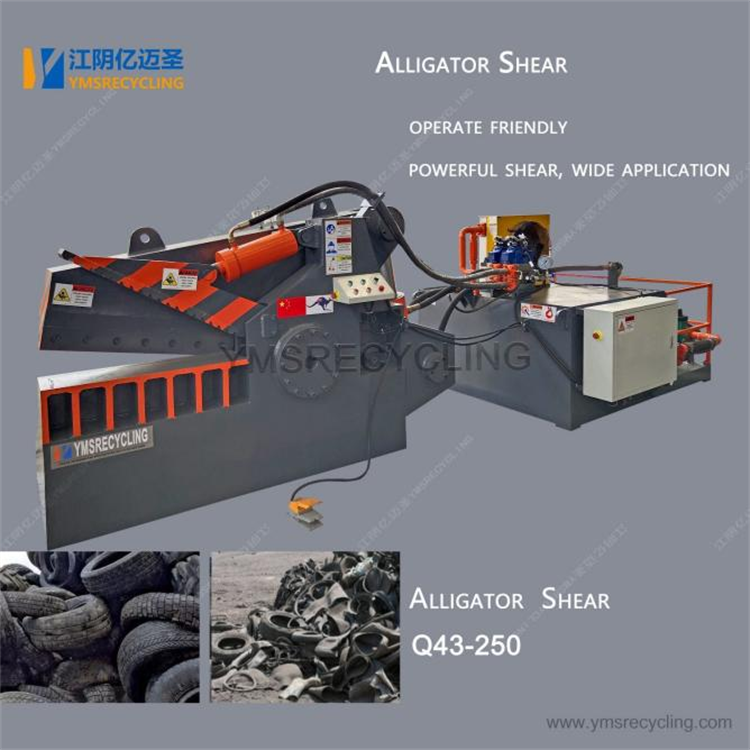

The core power of the hydraulic metal shearing machine comes from the hydraulic transmission system. This system is like the blood circulation of the human body. Through the flow of high-pressure liquid (usually hydraulic oil), the mechanical energy generated by the power source (such as an electric motor or an internal combustion engine) is converted into liquid pressure energy, and then converted into powerful linear motion or rotational motion through a precisely designed hydraulic cylinder. This conversion process is not only efficient, but also enables smooth transmission and precise control of force, so that the shearing machine can also show flexibility and strength when facing extremely hard metal materials.

In the world of metal processing, precision is an important yardstick for measuring the quality of a device. The hydraulic metal shearing machine uses an advanced CNC system, combined with high-precision sensors and servo control technology, to achieve millimeter-level or even micron-level control of cutting position, angle, and depth. Whether it is heavy steel plates, hard alloys, or metal parts of complex shapes, they can be easily and accurately separated under the "sharp blade" of this machine. This precise cutting ability not only improves production efficiency, but also ensures the stability and consistency of product quality, laying a solid foundation for downstream processing links.

With the advent of the Industrial 4.0 era, intelligence has become an inevitable trend in the development of hydraulic metal shears. Modern shears are not only equipped with advanced touch screen operation interfaces, which realize intuitive and convenient human-computer interaction, but also integrate cutting-edge technologies such as the Internet of Things, big data, and cloud computing. Through remote monitoring and fault diagnosis systems, engineers can grasp the operating status of equipment in real time, warn of potential faults in advance, and greatly reduce downtime and maintenance costs.

While pursuing efficiency and intelligence, hydraulic metal shears do not forget their commitment to the environment. By optimizing the design of hydraulic systems, reducing energy loss and hydraulic oil leakage, and reducing noise and vibration pollution, these machines are striving to become a model of green manufacturing. With the advancement of materials science, more and more new environmentally friendly hydraulic oils are being used in shears, further reducing the negative impact on the environment. The efficient recycling and reuse of scrap metal is also an important contribution of hydraulic metal shears in promoting the circular economy and achieving sustainable development.

As a leader in the field of metal processing, hydraulic metal shears are constantly promoting the progress and development of the industry with their powerful cutting capabilities, precise process control, intelligent operating experience and firm commitment to environmental protection. In the days to come, with the continuous innovation of technology and the continuous deepening of application, hydraulic metal shears will shine more brightly and contribute more to the construction of a more efficient, intelligent and green metal processing industry chain.