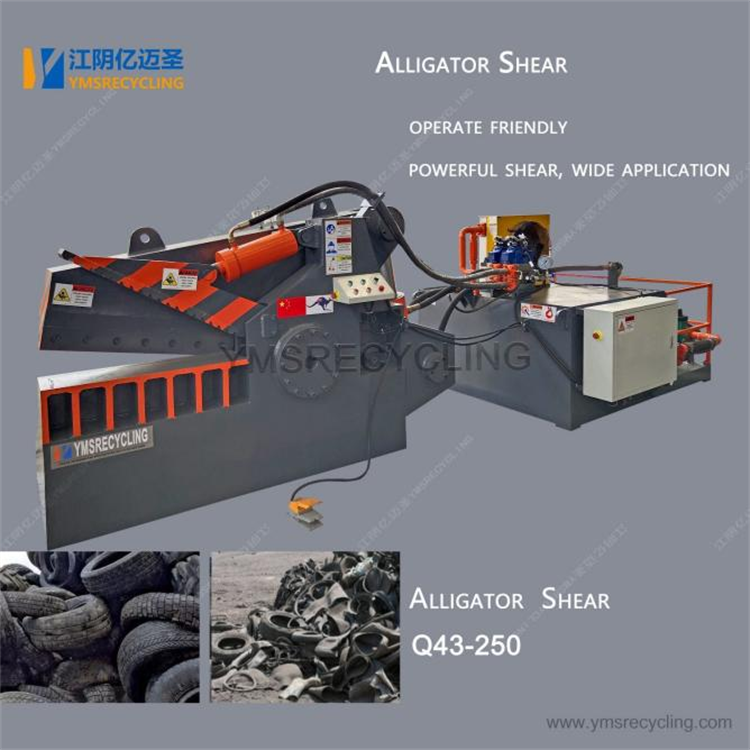

Heavy scrap metal shear machines, with their unique environmental protection value, play an indispensable role in the field of metal recycling and reuse.

If scrap metal is not properly handled, it will not only occupy a large amount of land resources, but also release harmful substances through weathering, corrosion and other processes, causing pollution to soil, water sources and even air. The heavy scrap metal shear machines use its powerful shearing ability to quickly and accurately shear scrap metal into small pieces or particles that are easy to handle, laying a solid foundation for subsequent classification, sorting, purification and other work. This process effectively reduces the exposure time of scrap metal in nature and reduces its potential threat to the environment.

The recycling of scrap metal is an important part of the circular economy. The heavy scrap metal shear machines use efficient and precise shearing processing to convert scrap metal into reusable raw materials and put it back into the production chain. This not only reduces the demand for mining of primary mineral resources, reduces energy consumption and carbon emissions during mining, but also extends the service life of metal resources and maximizes the utilization of resources. In this process, the heavy-duty scrap metal shearing machine has become a bridge connecting scrap metal and renewable resources, and has made an important contribution to the construction of a green, low-carbon circular economy system.

Scrap metal is prone to generate noise, dust and other pollutants during stacking and processing, which has an adverse impact on the surrounding environment and residents' lives. The heavy-duty scrap metal shearing machine adopts advanced noise reduction and dust removal technology, which effectively reduces the noise and dust emissions during the operation process and protects the cleanliness and tranquility of the surrounding environment. At the same time, by improving the recovery and reuse rate of scrap metal, it reduces soil pollution, water pollution and air pollution caused by improper treatment methods such as landfill and incineration, and makes positive contributions to the protection and restoration of the ecological environment.

With the enhancement of global environmental awareness and the continuous improvement of environmental protection policies, governments of various countries have introduced a series of policies and measures to encourage the recycling and reuse of scrap metals. As one of the core equipment in this field, the environmental protection value of the heavy-duty scrap metal shearing machine has been widely recognized and supported. It not only meets the requirements of international environmental protection standards and sustainable development goals, but also wins policy benefits and market opportunities for enterprises. By using heavy scrap metal shear machines for scrap metal processing and recycling, enterprises can not only reduce production costs and improve economic benefits, but also establish a good environmental image and enhance social responsibility.

The wide application of heavy scrap metal shear machines has also promoted the technological progress and innovation of the entire scrap metal processing industry. With the continuous upgrading and iteration of technology, the performance of the shears is more superior, the operation is more convenient, and the environmental protection effect is more significant. This not only improves the efficiency and quality of scrap metal processing, but also drives the coordinated development of related industrial chains. At the same time, the continuous innovation of shearing machine technology has also injected new vitality and motivation into the industry, and promoted the transformation, upgrading and sustainable development of the entire industry.