With the acceleration of industrialization and the prevalence of consumerist culture, the treatment and reuse of scrap metals has become one of the key issues for global sustainable development. Scrap metal recycling is not only an effective protection of natural resources, but also an important way to achieve a circular economy and reduce environmental pollution. In this context, as a pioneer in technological innovation, scrap metal recycling machines are leading a green revolution, redefining the boundaries of metal resource recycling with a new perspective and efficient means.

Traditional scrap metal recycling methods often rely on manual sorting, which is not only inefficient, but also prone to errors, resulting in waste of resources. Modern scrap metal recycling machines use advanced sensing technology, image recognition and machine learning algorithms to achieve high-speed and accurate sorting of scrap metals. These machines can automatically identify and distinguish different types of metals, such as iron, aluminum, copper, stainless steel, etc. Even tiny metal fragments mixed in waste can be accurately captured, greatly improving recycling efficiency and purity.

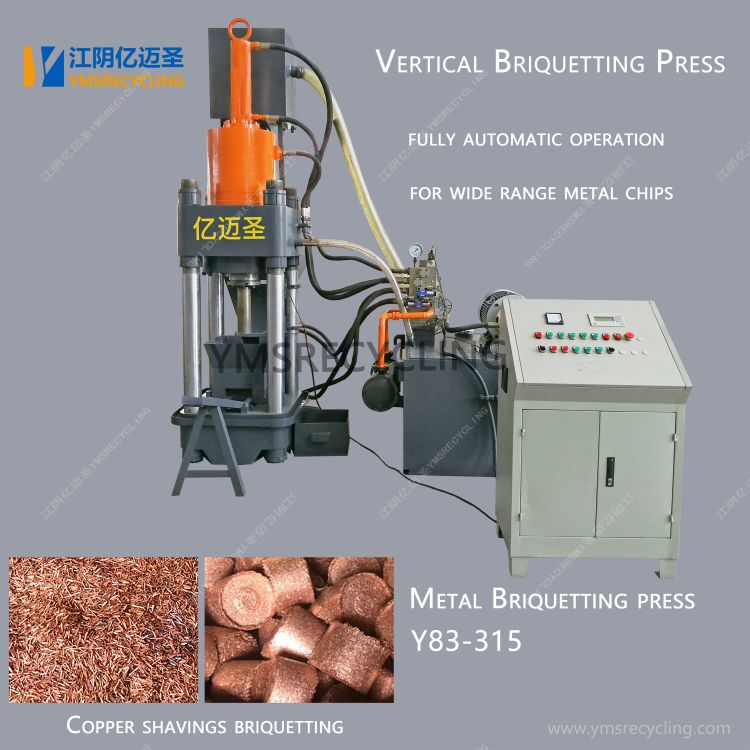

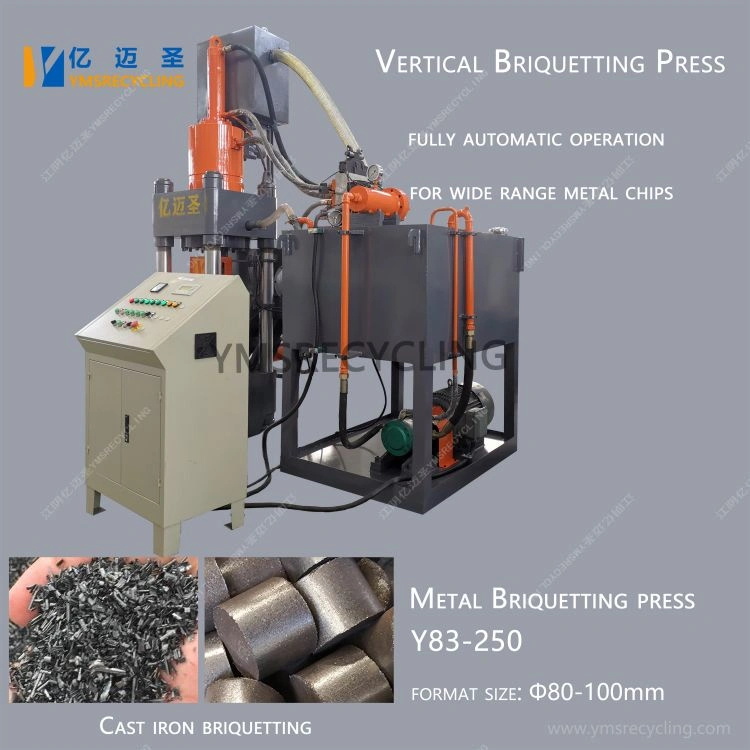

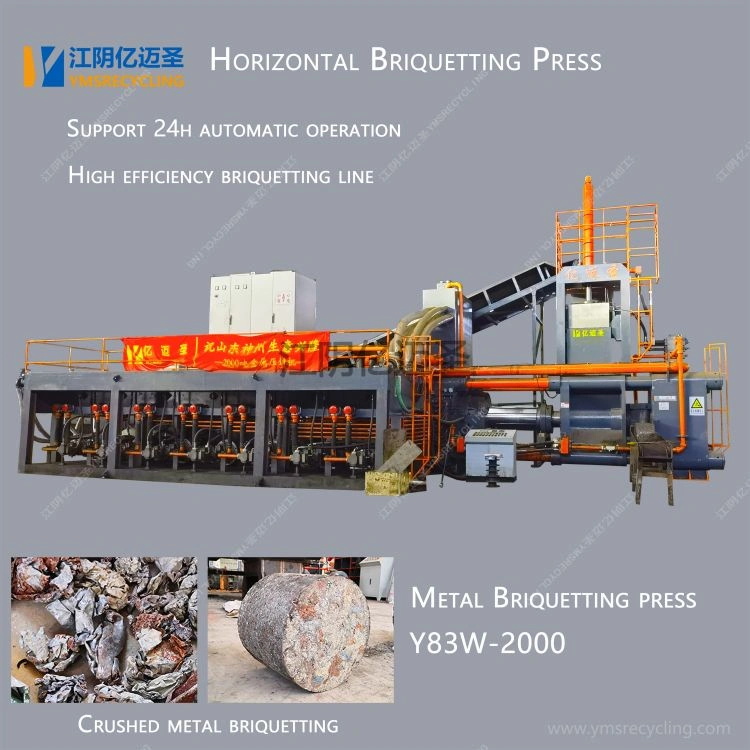

In addition to accurate sorting, scrap metal recycling machines also incorporate intelligent processing technology. Through built-in automatic cutting, crushing, briquetting and other devices, the machine can automatically adjust the processing parameters according to the different metal materials and shapes to process scrap metal in the most optimized way. This process not only reduces labor costs, but also further increases the value of recycled metals by reducing material losses and energy consumption.

Environmental protection and energy saving are the two major themes of modern industrial development. Scrap metal recycling machines were fully considered at the beginning of their design. With advanced energy-saving motors, optimized workflows and efficient energy recovery systems, these machines greatly reduce energy consumption and carbon emissions during operation. By reducing waste landfill and incineration, scrap metal recycling machines effectively reduce environmental pollution and contribute to the construction of a green and low-carbon production model.

The widespread application of scrap metal recycling machines has not only promoted the transformation and upgrading of the scrap metal recycling industry, but also provided new development opportunities for other industries. In the fields of automobile manufacturing, machinery manufacturing, construction industry, etc., these machines have become indispensable equipment, helping enterprises to achieve efficient recycling of waste materials, reduce production costs, and improve resource utilization efficiency. At the same time, with the advancement of technology and the reduction of costs, the application scope of scrap metal recycling machines will continue to expand, bringing the gospel of green transformation to more industries.

Looking to the future, scrap metal recycling machines will continue to develop in the direction of intelligence, efficiency and greenness. With the deep integration of technologies such as artificial intelligence and the Internet of Things, these machines will be more intelligently integrated into the entire recycling chain to achieve full-process automated monitoring and management. At the same time, with the continuous enhancement of people's environmental awareness and the continuous promotion of policies, the scrap metal recycling industry will usher in a broader development space. With the help of scrap metal recycling machines, mankind will move towards a greener and more sustainable future together.